|  |

|  |

|  |

|  |

|  |

|  |

Wednesday, December 10, 2008

Crane Accident due to operation mistake

Tuesday, December 9, 2008

Basic knowledge of Crane Operation (p.2)

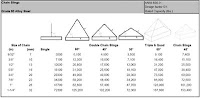

The angle at which a sling holds a given load influences the effective weight of the load. Stresses are minimal for loads with slings held perpendicular to the load, as shown in Figure A. For distributing the load vertically among more than a single leg of a sling, a spreader bar may be used. As shown in figures B-D, increasing the angle of the sling to the hook from 30 to 60 degrees increases the effective mass of the load from 1154 lbs to 2000 lbs, essentially doubling the weight on each leg of the sling at 60 degrees. The chart in the middle offers a handy guide for assessing the effective angle of the sling to the relative weight. Thus, it is always better to limit the angle of the sling. Further, such changes in sling angle must be accounted for in lifts that are close to the sling weight limit and/or for critical lifts (greater than 90% of the crane limit). Crane operators should download a copy of this chart and carry it with them during crane operations.

Sling position

Crane lifts require the use of slings. Slings are generally made of nylon or wire mesh. Nylon slings have the advantage of being easy to wrap around a load but can be easily cut or damaged if used improperly. Nylon slings which have been mishandled are subject to bleed-through. A red ink mark appears on the surface at the point of damage. Inspect all slings before use. Wire slings should have no more than two wires out of nine broken. Discard all damaged slings immediately. Rigging slings may be utilized in three basic manners. Each sling carries with it a label with rated weight limit capacities for vertical, choker, or basket configurations.

The basket configuration, which is analogous to using a spreader bar to distribute the weight on two legs instead of a single vertical sling, represents the highest rated capacity. This basket configuration is roughly twice as strong as the vertical configuration. A typical example would be a basket configuration with a 7200 lbs capacity would have a vertical capacity limit of only 3600 lbs. Taking a single sling and using it in the choker configuration would further degrade the capacity of the sling, dropping the rate of capacity of 3600 lbs in the vertical position to 2900 lbs in the choker position. Thus, in addition to the sling angle, sling position must be considered for all crane lifts.

Operating signal

crane operator does not, including: better view, knowledge of hazards, etc. Obey all STOP signals regardless of who gives them. Other than EMERGENCY STOP, signals should be accepted from only one person at a time (normally the spotter for the operator). Use standard crane signals and do not move unless directions are clear. Know standard hand signals (shown above). Hand signals are important because background noise may make communication difficult.

In order to make a safe lift the following information must be known

• Weight of item to be lifted (total).

• Center of gravity of the load.

• How to rig the load.

• How to control the load at all times.

The capacity of the CAMD crane is 4000 pounds. The weight limitation occurs because of the small hook attached to the lifting mechanism. Stabilization of the loads may be made possible by the use of a spreader bar, which gives 2 points of attachment, instead of the usual one point. The weight of the spreader bar must be included in the total weight of the lift. A crane scale is available to ascertain the total weight of the lift . Once the weight has been determined to be within the crane capacity, it is necessary to determine the center of mass. Loads not accurately balanced will tip or swing and result in a hazardous lifting environment. Light loads are apt to swing more readily and may require attachment of one or more tag lines to impair rotation of the load. This requires 1 or more individuals in addition to the crane operator.

• Do not sleep.

• Never divert attention when there is a load.

• Practical jokes are forbidden.

• Do not use alcohol or other intoxicants.

• Do not operate if taking medication.

Crane operation is a serious responsibility which should never be taken lightly. A properly trained crane operator will never approach another crane operator during a lift unless he/she observes a hazardous situation which requires immediate cessation of the lift. People with poor peripheral vision or diminished capacity due to ingestion of pain relievers, decongestant or other medication which may impair their mental acuity should not operate any crane. The use of alcohol or other intoxicants by crane operator is strictly forbidden and will result in loss of crane operator privileges.

• Lower the load to the ground.

• Disconnect the load and slings

• Raise all the hooks to upper limit switch.

• Place all controls to off position.

• Visually check for dangerous conditions

• Never leave a load unattended.

After completion of a safe lift, spot the crane in an approved location. The CAMD crane should never be left directly over the 90 degrees bending magnet of the storage ring because the bulk of the crane can act as a strong scattering force and contribute to sky shine radiation. Never leave a load attached to the crane and if you must absent yourself from the locale of the load, always take the controller with you. Always lower the load completely to the ground and give yourself some slack in the slings before attempting to remove the rigging from the crane hooks. Remember only vertical lifts must be made and dragging of the load horizontally is specifically forbidden. Ensure that the operator can see all potential hazards clearly at all times; otherwise, a crane spotter is necessary for all lifts. Once crane rigging is removed, return crane hook to upper limit switch. This will prevent the potential for the crane hook to hit any potential obstacles when the crane is next moved along its circular path.

• Make sure the load does not exceed rated capacity.

• Know the center of gravity of the load.

• Attach load above the center of gravity for stability.

• Select hitch that will control the load.

• Know the rated capacities of rigging and slinging

• Inspect all rigging before use

• Protect the sling from sharp corners.

• Allow for increased tension due to sling angle.

• Equalize loading on multiple leg slings

• Allow for load reductions when using choker hitches

• Attach tag line prior to lift.

• Keep personnel clear of lift area.

• Wear hard hats when making overhead lifts.

• Lift load a few inches and verify rigging.

• Check for any loose items.

• Know limitations of hoisting device.

• Start and stop SLOWLY! Watch for obstructions (not only hook and load but outboard end of the bridge).

• Check pathway is clear before making a lift (use a spotter for blind spots).

• Verify hook completely closes.

• Use appropriate hand signals.

• Maintain load control at all times.

• Report suspected drum wrappings immediately (if drum has fewer 2.5 wraps remaining).

• Never leave load unattended.

• Person must be 18 years of age and familiar with normal operating practices and procedures.

• Person must have good hearing and vision (with or without correction) and must have good depth perception.

• Person must not be afflicted with any known heart or other health conditions that might cause sudden loss of ability to react.

• Person must have been adequately instructed for crane operation.

• Operator must be qualified to rig the load safely. Qualification is a demonstrated ability to rig a load as a part of crane training.The operator must have recieved training which includes theory, practice and testing.

Before operating a crane with which the operator is not familiar, the operator must read the instructions provided by the manufacturer and note any special instructions, paying particular attention to the function and operation of each control.

Each crane operator should be held directly responsible for the safe operation of the crane or hoist. Whenever there is any doubt as to safety, the operator should stop the crane and refuse to handle loads until safe conditions have been restored. There is a minimum requirement of 18 years of age and fluency in the English language to operate the CAMD crane. Persons must also have good hearing and peripheral vision. These attributes are necessary for safe operation of the crane.

All crane operators must have have received training including: written materials; hands on experience; and testing of knowledge, both written and practical. Persons must also have had some training in the important fundamentals of rigging loads. Crane operators using a new lifting device must be familiar with the manufacturer's directions, noting any special instructions. No lifts over 100% rated capacity may be made without the prior written consent of the CAMD safety operator.

Basic knowledge of Crane Operation (p.1)

• Do not lift people and never ride the hoisting load.

• Do not lift load over people. No one shall be under the hoisting load.

• Make sure the sling is well balanced. Avoid tip loading, and loading on hook latch.

• Never lift the load over the rated capacity.

• Do not operate with kinked, twisted or damaged chain.

• Avoid side pull or end pull, and quick reversal operations.

• Never leave the suspended load unattended.

• Make sure you take up slack slowly.

In addition to improper rigging, cranes hitting overhead obstacles represent the most frequent hazards of crane operation. Before beginning a lift, clearly inspect the entire proposed path of the crane, paying particular attention to overhead obstacles (especially overhead electrical hazards which could be fatal) and whether the path of the crane will pass directly overhead of any individuals. Always have a spotter available, particularly in blind spots. Never exceed the crane capacity and never attempt a critical lift unless you have years of experience in utilizing the CAMD crane. A critical lift is defined as one exceeding 90% of the rated capacity of the crane. For the CAMD crane, a critical lift is greater than 3600 pounds. A crane is a vertical lifting device. It should never be used to drag or pull a load. Always position the crane directly perpendicular to the load to be lifted. Non-vertical lifts can

damage both the crane and the rigging materials and may result in improper wrapping around the drum. If the drum wraps are not seated in the proper position, immediately cease crane operation and inform facility maintenance. An operator who leaves a load suspended and unattended is subject to disciplinary action, which may include revocation of his or her license to operate the crane.

Checking Limit Switch

• Move crane to open area.

• No load should be on hoist lines.

• Slowly run (#2 position) block up to 3’ from limit switch and stop.

• Continue to raise hook slowly (#1 position).

• If limit switch does not operate at point where it should, don’t use crane.

The first procedure in any crane lift is to assess the valid performance of the limit switches of the crane. To accomplish this task, run the length of the crane rope to the lower limit. For CAMD, this limit is approximately 4 inches from the floor. Make sure that at least 2.5 wraps remain on the drum. Once the lower limit switch has been tested, raise the crane hook to the upper limit switch, all the while making sure the rope wraps correctly. There should be no cross wrapping or ill sitting of the rope on the grooves of the drum. Ensure the top limit switch stops before hitting the drum. As you approach the top limit switch slow the crane from the fastest position (3) to the slowest position (1) to prevent hitting the upper limit. If either limit fails the crane should be locked out. The electrical control panel for the operation of the crane is to the left of the experimental hall door (on the receiving side) adjacent to the log-out tags. Pull the lever down to place in the off position.

Inspection and Maintenance

• Inspection and lubrication are done twice yearly.

• Daily before operating:

o Check battery

o Check all controls

o Visually inspect

Wire rope for kinks or damage

Sheaves, drums for damage

Upper and lower limit switches.

CAMD maintains a rigorous inspection program. All maintenance is performed only by qualified personnel. Being a qualified CAMD crane operator does not qualify one as maintenance personnel. Maintenance is required whenever a wire has wrapped incorrectly on the drum or a limit switch fails in either the upper or lower modes. In case of any suspected failure the operator must immediately cease operation, remove power from the crane and inform the facility management or CAMD safety. Place a lockout tag on the remote control unit. All CAMD crane operations are conducted using the portable remote control for the crane. After retrieving the remote control, check the level of the battery. If the battery does not register in the green, replace the battery before continuing. Collect suitable slings for properly securing all loads. Examine slings for any defects.

Before beginning any lift, check upper and lower limit switches without any weight attached. The crane limit is 2 tons (4000 pounds) which must include the weight of all rigging equipment. A scale is available to check overall weight. Once the crane has been established to be working properly, rig the load properly, attaching tag lines for loads which might be susceptible to swing. Always ascertain that the area over which the load will travel, is free and clear of personnel or other potential obstacles.

Rigging

• Loads should be well secured.

• Slings should be adequate to the task.

• Slings should be unkinked and load balanced and secured.

• No sudden stops.

• No obstructions while lifting or traveling.

• No loose items on load or crane before lift.

• Bumping into runway stops is prohibited.

• Hoist line must be vertical prior to the lift (remove slack in the hoist slowly).

• No crane load should pass overhead of personnel, clear the area before making the lift.

• No one is to ride the crane without permission.

The most important job of any crane operation is rigging of the load. Poor rigging may result in personnel injury, property damage, or other serious hazards. Rigging is the most time consuming of any crane operation and represents the single most hazardous potential of crane operation. In a multi-sling operation, each leg must be of the same length and must contribute equally to load distribution. Nylon slings are susceptible to damage by sharp corners on the item to be rigged. Caution must be taken to ensure that slings are not damaged by sharp corners or by excessive loading. Rigging requires years of practice to perfect. If in doubt about the security of your rigging, ask for help.

Rigging should be checked by lifting the load a few inches off the ground to ensure that no swing develops and that the load is completely secure. Remember it is important to take the time to accomplish this task correctly. Not doing so may result in catastrophic consequences. One of the most important things to check before lifting a load is to look for loose items, such as screws or tools which may have been used to secure the load. Such items can become projectiles during a lift. This is the reason why crane operators or especially tag line operators should wear hard hats when operating the crane and why it is essential to make sure the path of the crane does not pass over the head of any individual.

It is always important in rigging practice to rig the load so that it is stable. A stable load is one in which the center of gravity of the load is directly below the main hook and below the lowest point of attachment of the slings.The center of gravity of an object is that point at which the object will balance. The entire weight may be considered as concentrated at this point. A suspended object will always move so that the center of gravity is below the point of support. In order to make a level or stable lift, the crane or hook block must be directly above this point. Thus a load which is slung above and through the center of gravity will be stable and will not tend to topple or slide out of the slings.

Predicting the center of mass for an object to be lifted is not a trivial matter. It may require several attempts at rigging to find the appropriate balance point. Many objects are not rectangular such that predicting the center of mass is often difficult. In all crane lifts the center of mass must remain below the hook and below the point of attachment for any rigging. A center of mass above the hook is inherently unstable and will cause the load to flip. Similarly, loads which are not balanced in the horizontal plane may slip from the rigging. The overall stability of the load is a combination of balance with respect to center of mass, weight distribution, and rigging tightness.

Sling types for lifting activites

Wire Rope Slings ASME B30.9

(1) Minimum 10 times the rope diameter between splices or sleeves.

(2) Horizontal sling angles less than 30 degrees should not be used.

(3) All swaged socket and poured socket assemblies shall be proof tested.

(4) Consult manufacturer if temperatures are below 60 degrees F or above 400 degrees F.

(5) Welded end attachments shall be proof tested.

(6) Eyes shall not be formed using knots.

(7) Wire rope clips shall not be used to fabricate slings.

(8) Remove from service if: abrasion, kinking, crushing, heat damage, broken wires (10 in one lay or 5 in one strand in one lay), distortion, damaged end attachments, hooks with 15% spread or 10 degree twist.

(9) Slings shall not be used at load greater than rated capacity.

Alloy Steel Chain Slings ASME B30.9

(1) Slings shall not be used at a load greater than rated capacity.

(2) All welded slings shall be proof tested by the sling manufacturer.

(3) Mechanically assembled slings shall be comprised entirely of proof tested components.

(4) Slings shall have permanently affixed identification stating size, grade, rated load and angle on which the rating is based, reach, number of legs, and sling manufacturer.

(5) Consult mfg. if temperatures are below -40 degrees F or above 600 degrees F.

(6) Attachments or components shall have a rated load equal to the alloy chain.

(7) Slings shall be inspected for damage by a designated person making a record of the conditions, at least annually.

(8) Repairs shall be made only by the chain mfg. or qualified personnel.

(9) Removal Criteria: missing or illegible sling identification, wear, nicks and gouges, cracked or broken, bent, weld splatter, heat damage and throat opening or twist in hooks.

Synthetic Web Slings ASME B30.9

(1) Slings shall not be used at a load greater than shown on its tag.

(2) Horizontal angles less than 30 degrees should not be used.

(3) Each sling shall be permanently marked to show: name of the manufacturer, code or stock number, rated loads for the type of hitches used, any type of synthetic web material.

(4) Reused or welded fittings shall be proof tested 2 times the rated load.

(5) Slings shall be repaired only by a sling manufacturer or qualified person.

(6) Temporary repairs shall not be permitted.

(7) Repaired sling shall be proof tested to two times the rated load.

(8) Periodic inspections should be conducted at least annually, with written inspection records.

(9) Removal Criteria: acid or caustic burns, melting or charring, holes tears, cuts, or snags, broken or worn stitching, excessive abrasive wear, knots, damaged, cracked or broken fittings.

Utility Rigging Charts

Whenever any sling is used, the following practices shall be observed:

(1) Slings that are damaged or defective shall not be used.

(2) Slings shall not be shortened with knots or bolts or other makeshift devices.

(3) Sling legs shall not be kinked.

(4) Slings shall not be loaded in excess of their rated capacities.

(5) Slings used in a basket hitch shall have the loads balanced to prevent slippage.

(6) Slings shall be securely attached to their loads.

(7) Slings shall be padded or protected from the sharp edges of their loads.

(8) Suspended loads shall be kept clear of all obstructions.

(9) All Employees shall be kept clear of loads about to be lifted and of suspended loads.

(10) Hands and fingers shall not be placed between the sling and its load while the sling is being tightened around the load

(11) Shock loading is prohibited.

(12) A sling shall not be pulled from under a load when the load is resting on the sling.

(d) Inspections . Each day before being used, the sling and all fastenings and attachments shall be inspected for damage or defects by a competent person designated by the employer.

Additional inspections shall be performed during sling use, where service conditions warrant. Damaged or defective slings shall be immediately removed from service.

Source: ebook4down.blogspot.com

Hand signals for crane operation

Below is the list of hand signals by picture.

Crane Accessories Usage

* Shackle style: bow shackle and dee shackle

* Safe use of eyebolts - Side loading: do not apply any sideloading to eyebolts. They can be bent.

* Safe use of eyebolts - Included Angle: included angle not to exceed 90 degree

* Eyebolt Alternatives: Rud lifting link, Crosby lifting link, Rud self-aligning Eyebolt

* Swivels: swivels allow slings that are connected to a load untwist.

* Turnbuckles and Bottlescrews

* Plate Clamps: vertical clamp, horizontal clamp

* Spreader Bar: spreader bar must be marked with:

+ Identification number

+ S . W . L

+ Tare Weight

* Safe use of spreader bar: the lifting slings for the load must be connected to the spreader directly below the lifting lugs connecting the slings to the crane hook

* Roofing spreader bar

* Lifting beam

* Shackle marking: shackle must be stamped or permanently marked on the body with the lifting capacity, expressed as either S.W.L. or W.L.L.

* Shackle defects: defects that will condemn a shackle

+ Bent or twisted body

+ Deformation

+ Cracks

+ Wear (max. 10%)

+ No SWL marking

+ Damaged or bent pin

+ Thread damage

* Remote release shackles

* Eyebolt Types:

+ Plain eyebolt: single sling vertical lifts only

+ Collared eyebolt: multiple sling point applications. the eyebolt collar must be bearing on the surface of the load.

Crane Load Charts

Note:

1. The rated lifting capacity shown in the chart is a combined maximum weight that are include:

The weight of the hook block

+

The weight of the lifting equipment

+

The weight of the load

+

Any other amount as specified by the manufacturer in the Condition of Use

2. The operating Radius:

Operating radius is the horizontal distance from a known point on the crane (usually the centreline of rotation) to the centre of gravity of the load.

3. Overloading of the crane can cause either overturning or structural damage or failure.

Guidelines for Crane Operation

The most important is how to control and operate in safety condition. Here is general guidelines for crane operation regarding the moving, set up and lifting stages.

* The wheels of a Locomotive Crane must be chocked when working on an incline.

* When lifting a load would you use rail claps instead of outriggers on a Locomotive Crane.

* Ground stability for Mobile Cranes: working close to backfilled ground or an excavation may cause the ground sink or collapse under the exerted pressure of the outriggers, crane weight and the load.

* Correct outriggers extension: do not let the wheels are carrying the load or the outrigger beams are not fully extended. Proper usage of outriggers with tyres clear.

* Outrigger Packing: each layer of packing must be at right angles to the previous layer.

* Load bearing pressure: bearing pressure must be check for outriggers stability. For example: soft clay~ 8ton/m2, dry sand ~40ton/m2, shale~ 80t/m2, dry clay 30t/m2, gravel~50ton/m2....

* Area of packing: determining (by formula) the area for outriggers packing before setting up.

* Setup summary:

+ Outrigger pads are on solid footing or blocking / crane is set up level on firm, stable ground or blocking.

+ All wheels are clear of ground.

+ All outrigger beams are fully extended.

+ Boom angle, boom length and load radius are known and the crane's rated capacity is known.

+ Load weight is known.

+ The hook is directly above the load's C of G

* Crane selection guides:

1. Maximum Radius

2. Weight of Load

3. Clearance Height under Obstructions

4. Distance from Jib Head to Hook

5. Distance from Hook to Ground.

6. Height of Obstruction between Crane and Load

7. Obstructions hindering Counterweight

8. Distance from Crane to any Obstructions

9. Boom Length

10. Ground Condition and other Overhead Services

Note: The total weight of the load is obtained by adding the actual load weight to the weight of crane hook, block, slings, spreaders, shackles and any other lifting attachment- the total of which must not exceed any load capacity listed on any crane rating chart.

Operating factors vary significantly from crane to crane. Always refer to crane operator for guidance and advice.

* Common Obstacles:

+ Overhead Obstructions

+ Personnel at construction site or lifting area.

+ Powerlines

+ Underground services

+ Pedestrians on traffic flow

+ Potholes/soft/rough ground.

* Dual lifts require intermediate riggers certificates:

The person in charge of a multiple crane lifting operation needs to hold which certificate?

* Safe mobiling:

When mobiling a load up an incline , what can happen to a near vertical crane boom?

Why should a mobile crane carrying a load be directed down the incline in reverse?

* Do not drag loads:

Dragging a load can cause structural damage to a crane, damage to the load or damage to the lifting equipment.

The load can swing uncontrollably.

* Danger points:

Personnel must not stand near the chassis of a slewing crane as a person could be jammed or crushed between the slewing upper and stationary lower crane sections

* Boom deflection near overhead powerlines:

Caution, the boom will spring up after the load is released.

* Hand held tag lines:

+ The minimum size of fiber rope for hand held taglines is of 16mm diameter

+ When working near overhead powerlines ensure taglines used are made of non-conductive material such as nature fiber, not synthetic.

* Power Clearance AS2550: take into account that the clearance from live aerial conductors must be sastisfied.

* Safety observer zone: the crane or plant is operating in the " safety observer zone " when any part of the crane or load COULD enter the exclusion zone. Encroachment into the exclusion zone is still strictly forbidden.